The Story of Sam Nichols' MGB

Sam Nichols’ prized 1973 MGB, his first new car, was purchased on July 28, 1973 from Rogers Pontiac-Cadallic in Shelby, NC. After a lot of fun miles, “B” was last driven in 1992 and was then stored in Sam’s garage. Almost 20 years passed but in 2011 the plans for restoration were engaged and “B” was taken to a body shop in Bessemer City for a total mechanical restoration, new paint and a new interior. The car was painted but remained at the body shop for over three years without the remaining restoration being completed. “B” was then moved to a friend’s shop back in Shelby and stored for about two years. Thanks to an idea by fellow BREMC member Curt Holland, Sam’s valued “B” was made into a club project and Curt graciously offered his basement shop for the completion of the restoration. Members of BREMC volunteered and worked together on Sunday afternoons for months and months……………finally, on April 2, 2017, Sam’s 66th birthday, Sam drove his “treasured” MGB for the first time in twenty-five years. “What a birthday present!!!”

Beautiful paint job…yes. Functional brakes… not so much! With that in mind, we removed the rear bumper so Curt could use the T-Bar on his tractor to ease “B” down the incline into his shop.

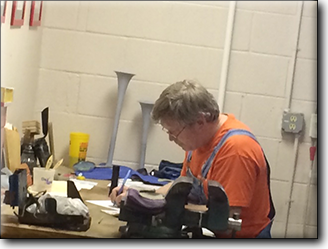

Curt putting together the dreaded parts list that Sam needs to order.

Curt putting together the dreaded parts list that Sam needs to order.

"B" is in position for the club members to finish the restoration and get it back on the road.

"B" is in position for the club members to finish the restoration and get it back on the road.

The gasket between the windscreen frame and the body was 40+ years old and it was in real need of replacement. Don't try this at home because taking the windscreen off is the easy part!

The gasket between the windscreen frame and the body was 40+ years old and it was in real need of replacement. Don't try this at home because taking the windscreen off is the easy part!

If you ever have the opportunity to install a windscreen gasket on an MGB.......DON'T ! Without a doubt, this has to be the worst job ever for working on MGB's. It is impossible to get that &$#@ gasket to compress enough to get all four bolts in that hold the windscreen frame. We wound up using clamps and time. Every day for a week Curt would tighten each clamp a little, until the gasket compressed enough to allow the bolts to be installed. How did they do this at the factory?

If you ever have the opportunity to install a windscreen gasket on an MGB.......DON'T ! Without a doubt, this has to be the worst job ever for working on MGB's. It is impossible to get that &$#@ gasket to compress enough to get all four bolts in that hold the windscreen frame. We wound up using clamps and time. Every day for a week Curt would tighten each clamp a little, until the gasket compressed enough to allow the bolts to be installed. How did they do this at the factory?

Bruce was a big help working under the dash. He owns an E type Jag, so under dash work on an MG is a cake walk compared with an E type!

Bruce was a big help working under the dash. He owns an E type Jag, so under dash work on an MG is a cake walk compared with an E type!

With the windscreen in place, Sam is installing and tightening the nuts that hold the dash panel in place.

With the windscreen in place, Sam is installing and tightening the nuts that hold the dash panel in place.

The brake and clutch systems were completely refurbished, starting with brand new master cylinders for the brake and clutch circuits. The bracket that holds these was blasted and painted with catalyzed black for durability. New gaskets were installed under the bracket to make it all water proof too.

The brake and clutch systems were completely refurbished, starting with brand new master cylinders for the brake and clutch circuits. The bracket that holds these was blasted and painted with catalyzed black for durability. New gaskets were installed under the bracket to make it all water proof too.

Skip (left) and Doug (right) are working on and studying how to get the bolts and screws in the cover that goes over the end of the pedals. We used stainless screws this time, so they won't rust and stick again.

Skip (left) and Doug (right) are working on and studying how to get the bolts and screws in the cover that goes over the end of the pedals. We used stainless screws this time, so they won't rust and stick again.

Jeff Dreibus (left) and Doug Carlisle (right) replace the hoses.

Jeff Dreibus (left) and Doug Carlisle (right) replace the hoses.

The club finished our work and Sam drove his MG for the first time in decades. It was also his birthday! Happy Birthday Sam!

The club finished our work and Sam drove his MG for the first time in decades. It was also his birthday! Happy Birthday Sam!

Happy fellow driving his beloved MG back home. This was a great BREMC project and all involved really enjoyed it.

Happy fellow driving his beloved MG back home. This was a great BREMC project and all involved really enjoyed it.

From Sam... "I could never express enough gratitude and thanks to everyone involved in this project."